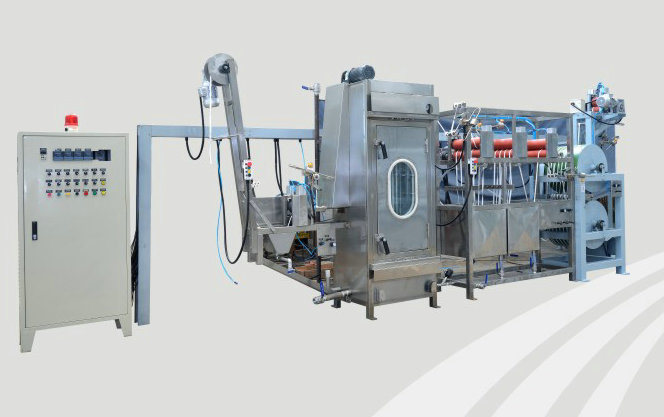

18 Years Factory Woven Edge Ribbons Winding Machine - High Temperature Single Tape Sample Dyeing Machine – Kin Wah Detail:

Basic Info

Product Description

Item No: KW-888

Size: 5900*800*2400mm

This is a kind of high speed single end satin ribbons,elastic tapes sample continuous dyeing&finishing machine.

Features:

1) High efficiency

2) With elongation and Calender functions

3) Our patents.

4)Application: The dyeing machine is especially used for

satin ribbons,nylon elastic tapes with width of below 25mm sample making or small production.

Production capacity: 1Pcs/time,0-30meter/min/Pcs.

| Item | |||

| Heat System | electrical | steam | |

| Working Width(mm) | 400 | 600 | |

| Thermofixation Chamber Tape Content(m) | 45/60 | 45/60 | |

| Maximun Speed(m) | 15 | 25 | 25 |

| Maximun Number(m) | 1 | 1 | |

| Control system | Manual/PLC |

Processes: Feed in-dyeing groove-color fixation chamber-washing tank-Chemical groove-Drying&finishing unit-take off

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.

Product detail pictures:

Related Product Guide:

Chile: Despite super harvest cherry producers can’t cover their costs | Luggage Belt Continuous Dyeing And Finishing Machine

Yes, Cars Still Come With Stick—Here Are a Few New Favorites | Luggage Belt Continuous Dyeing And Finishing Machine

We know that we only thrive if we can guarantee our combined price competiveness and quality advantageous at the same time for 18 Years Factory Woven Edge Ribbons Winding Machine - High Temperature Single Tape Sample Dyeing Machine – Kin Wah, The product will supply to all over the world, such as: Jamaica , Cyprus , Panama , Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

-

Chinese wholesale High Temperature Automatic Sc...

-

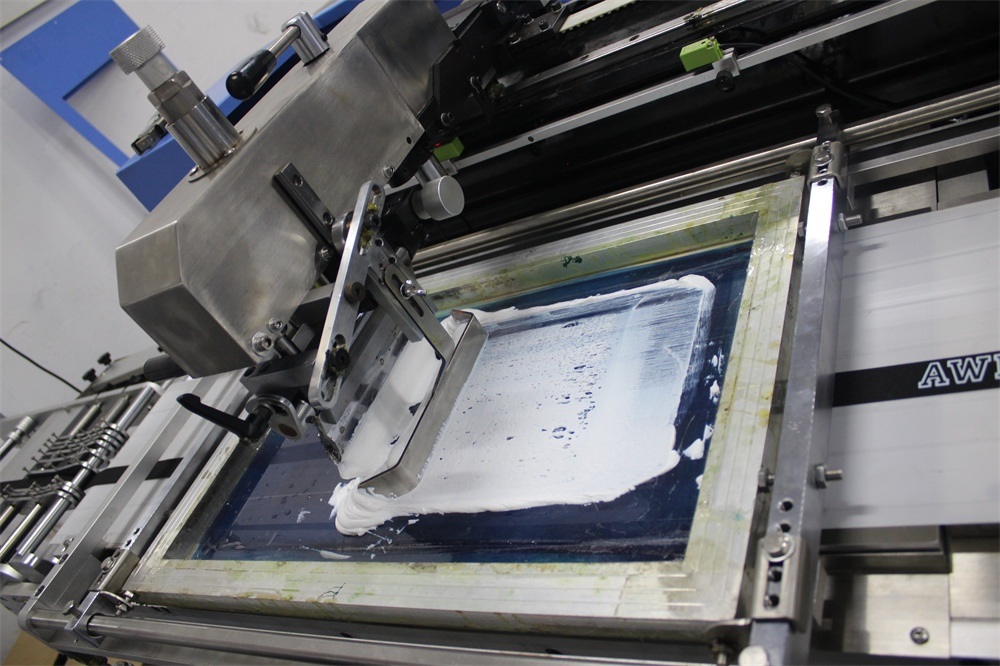

Factory wholesale Balloon Screen Printing Machi...

-

New Arrival China 8 Heads Labels Wrapping Machi...

-

Factory wholesale Polyester Tapes Winding Machi...

-

Hot sale Factory Polyester Shoulder Tapes Dyein...

-

Special Design for woven Fabric Screen Printing...