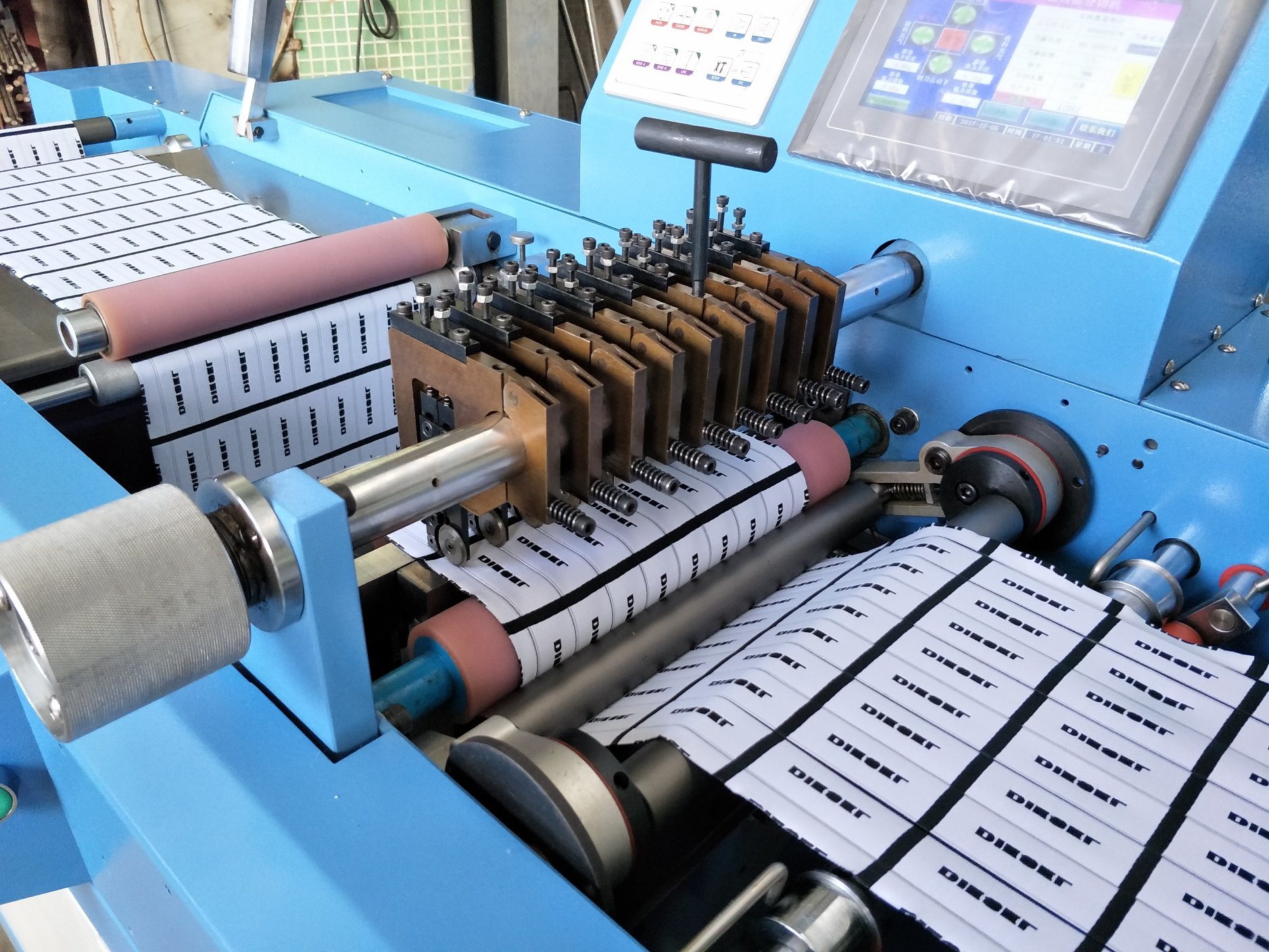

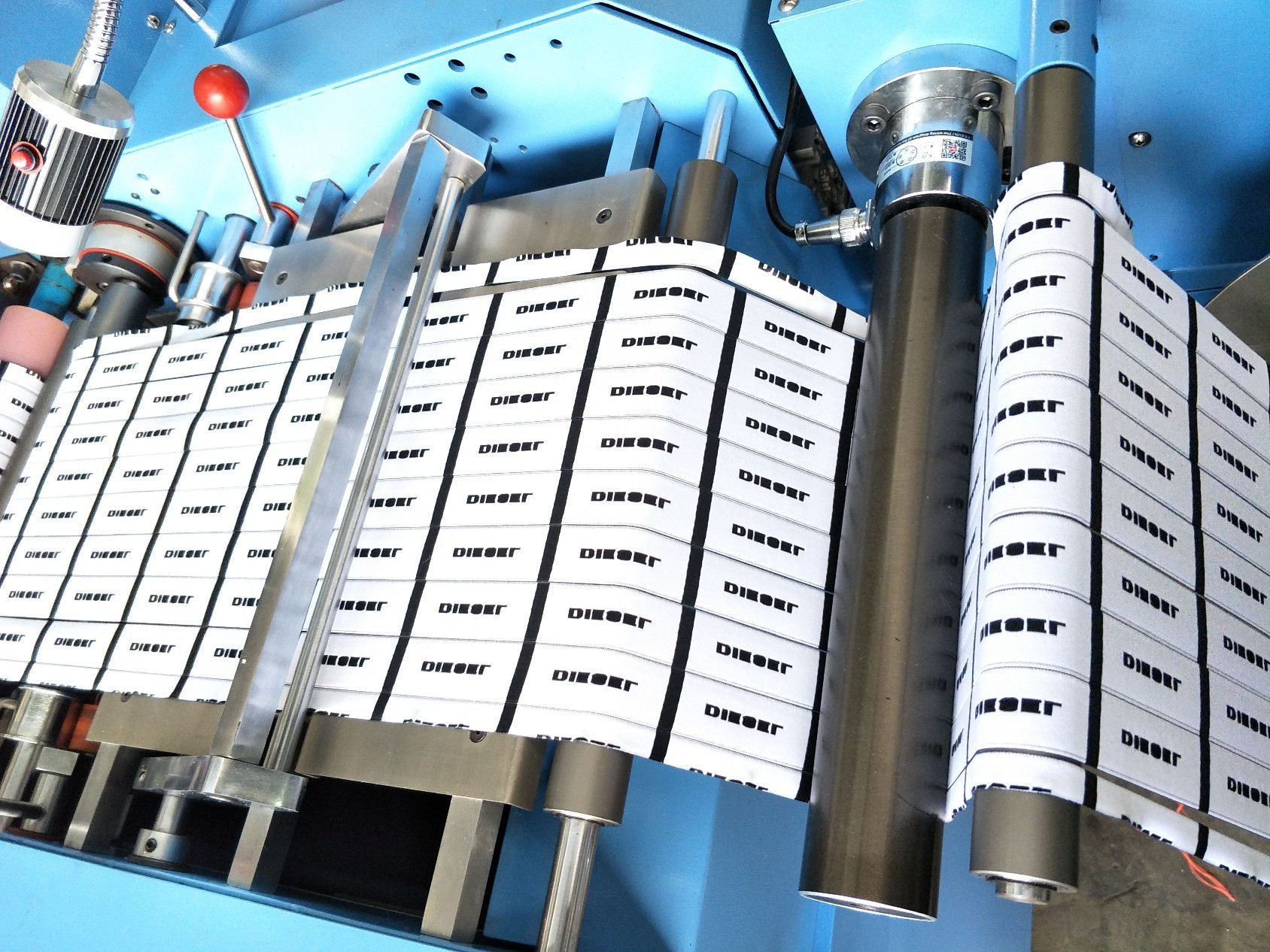

2017 Good Quality Vertical Flat Screen Printer - Woven Labels Ultrasonic Slitting Machine with High Efficiency – Kin Wah Detail:

Basic Info

Product Description

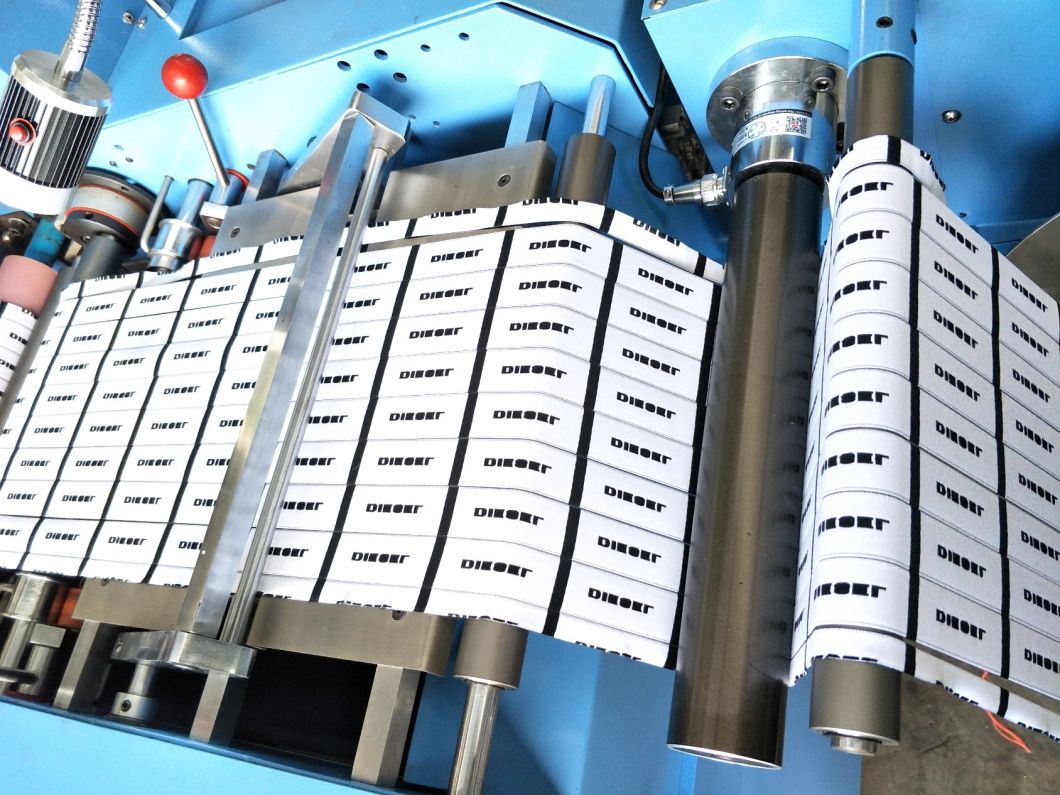

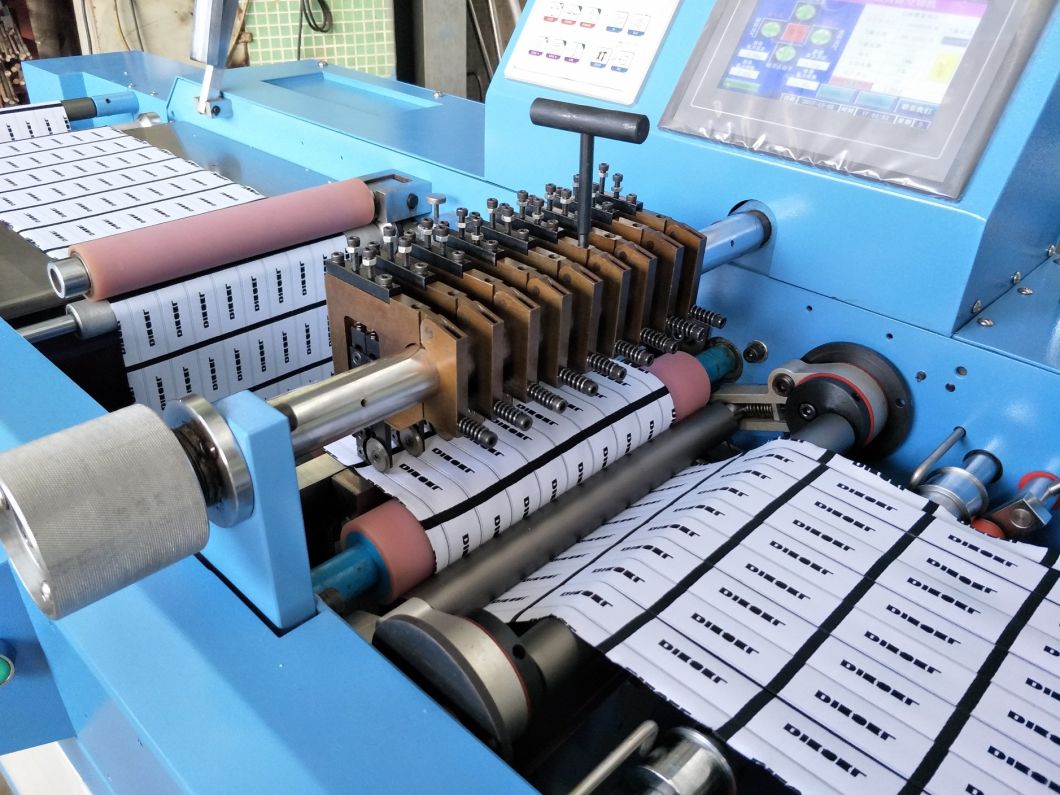

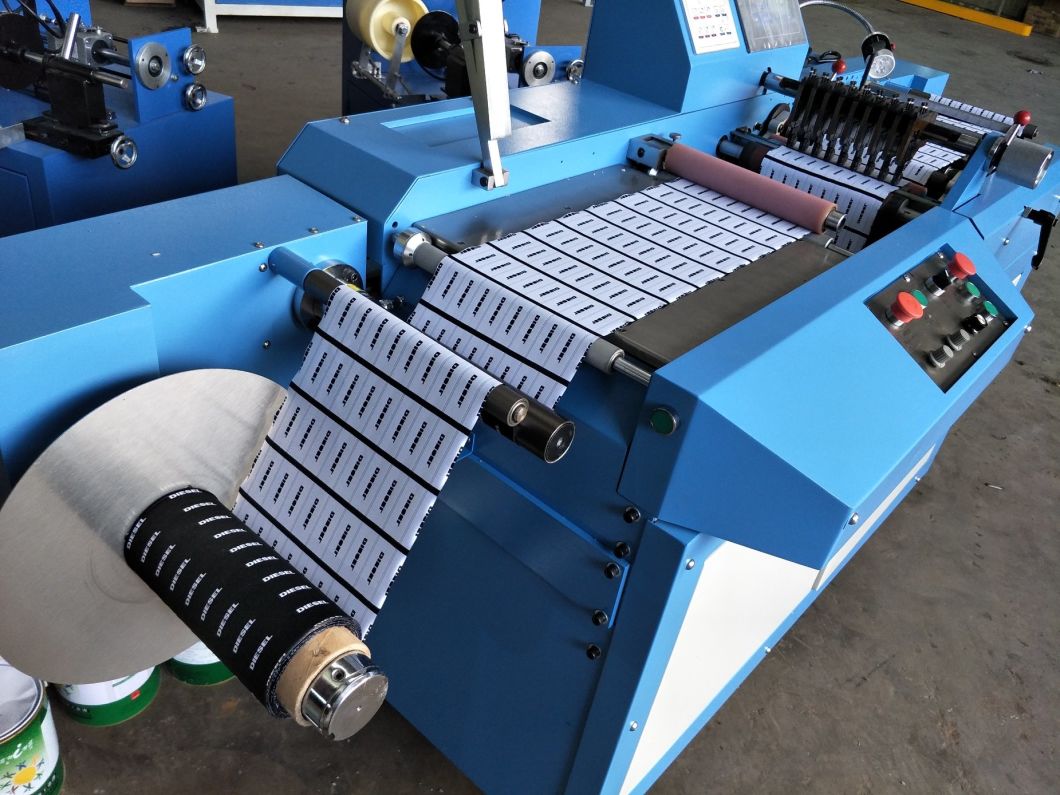

1)Application material: Suitable for slitting any roll Material labels,such as woven labels, metal labels and so on.

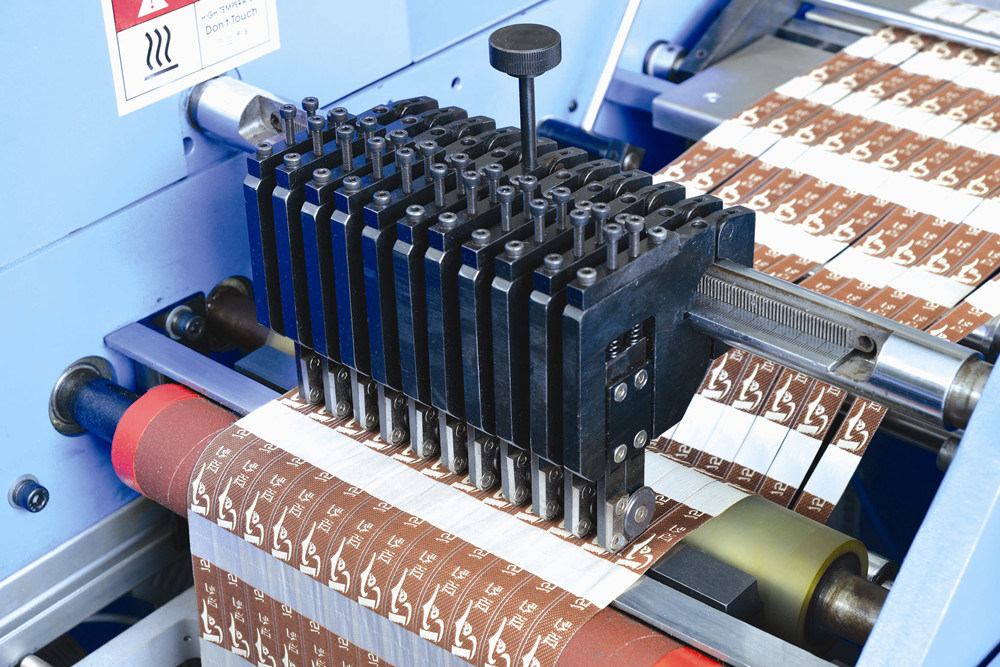

2)Ultrasoinic System Adopted 20KHZ-2000W original Switzerland ultrasonic oscillator combine with 20KHZ-3000W High efficiency Vibrator to get a high speed, high efficiency,High accuracy working performance and slitting edge is soft and smooth without raw edge.

3)Laid out Original America Rectifying Device to automatic adjust labels running well to make labels slitting work in more accuracy and more smooth to reduce defective products.

4)Ultrasonic head adopt TITANIUM ALLOY material.

5)Tension: Laid out Tension controller Magnatic (powder brake)for labels feed in

6) Laid out PLC and touch screen

D,Technical Specification:

1) Max. Slitting width: 25MM

2) Min. Slitting width: 6MM

3) MAX. Speed /H.: 16M/Min.

5) Power:4Kw/220V/3P/50 Hz

6) Machine size: 2500Mm(L) * 1000 mm(W) * 1250m(H)

Company Information

DOPSING Machinery Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&Label printing machine and mini High-Temperature Ribbon Screen Printer,all are for fabric label and ribbon screen printing.As the professional narrow fabric screen printing machine manufacturer,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co., Ltd.And moved into

KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Packaging & Shipping

Covered by plastic membrane within full container or less container (woodencase)

Product detail pictures:

Related Product Guide:

Zacks Investment Research Upgrades Ennis (EBF) to Strong-Purchase | 8 Heads Labels Winding Machine

Claire Foy cuts an elegant figure in all black as she joins Ryan Gosling at screening of First Man | Polyester Satin Ribbons Small Continuous Dyeing Machine

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for 2017 Good Quality Vertical Flat Screen Printer - Woven Labels Ultrasonic Slitting Machine with High Efficiency – Kin Wah, The product will supply to all over the world, such as: Poland , United States , Wellington , Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we've insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

We have been looking for a professional and responsible supplier, and now we find it.

-

2017 Good Quality 6 Heads Tapes Wrapping Machin...

-

Best Price on Head Film Screen Printer - 3colo...

-

100% Original Dye Sublimation Lanyard Machine -...

-

factory customized Smart Card Fingerprint Wifi ...

-

Factory source Non Woven Printing Machine - 2 ...

-

New Arrival China Flat Bed Silk Screen Printing...