China wholesale Inkjet Flatbed T Shirt Printer - Lashing Straps Screen Printing Machine with CE Certification – Kin Wah Detail:

Basic Info

Product Description

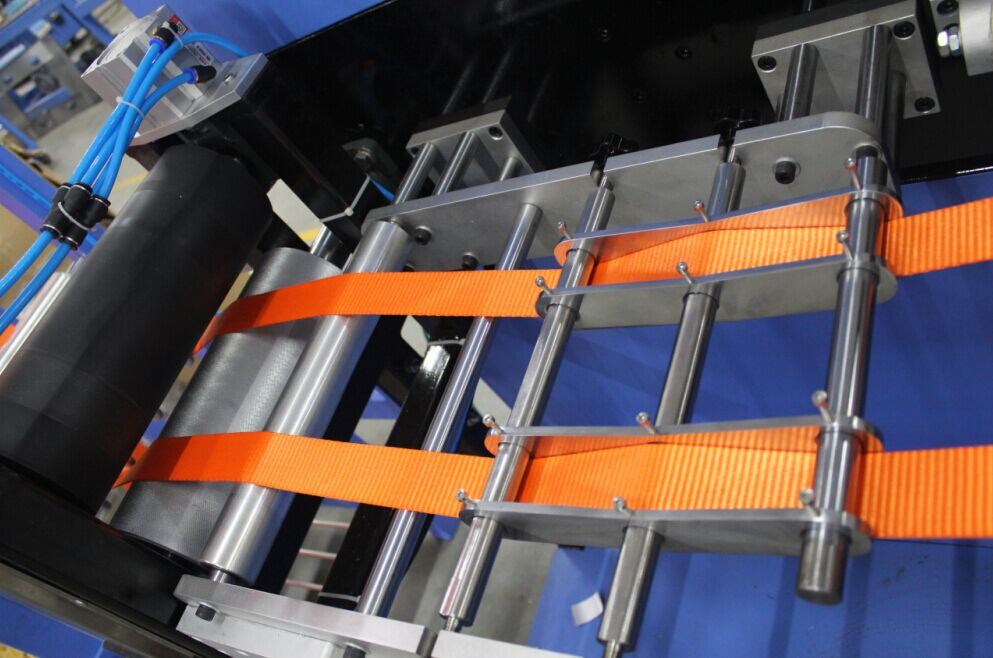

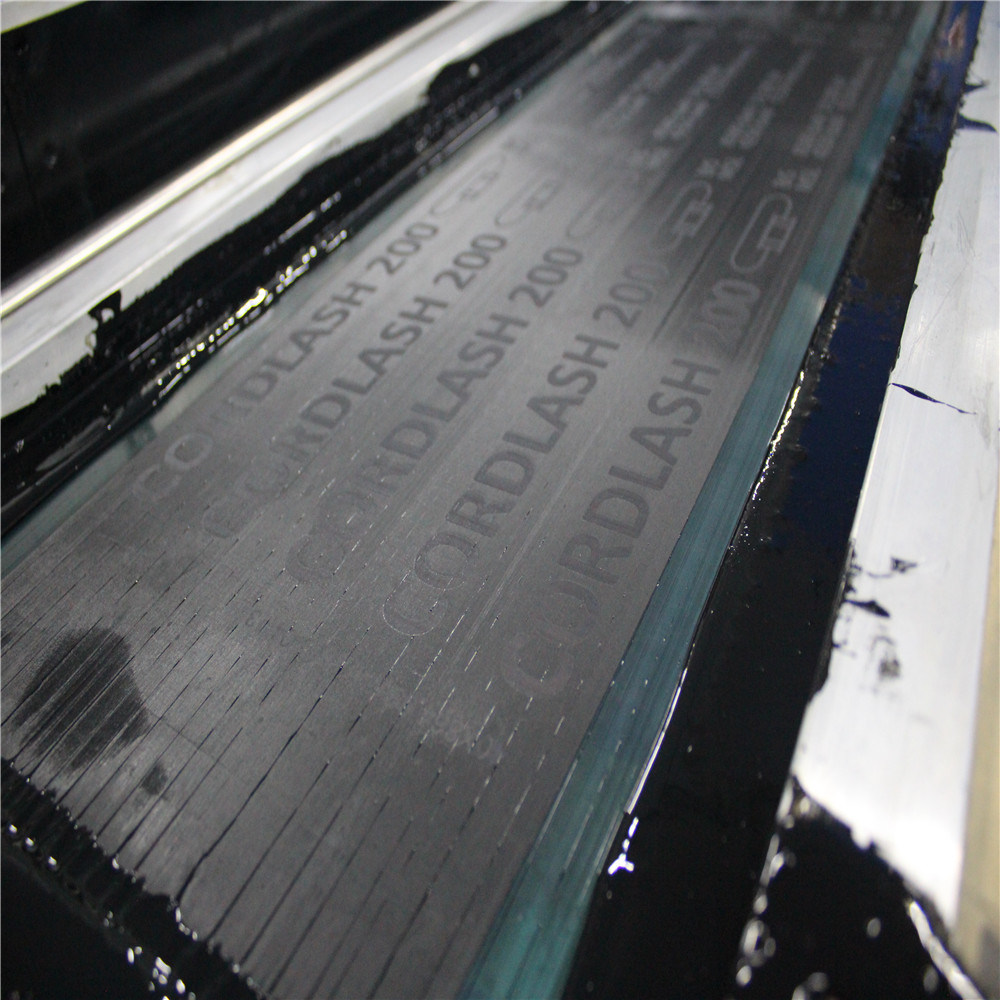

This is a kind of automatic textile lift slings webbings printing machine in screen printing type, with PLC and touch screen

1)Application material: print any kinds of roll to roll webbings, such as seatbelt webbings, tie down straps, luggage and suitacase webbings and so on.

2)Precisely Print any roll to roll material with width<30CM.

3)convey: powered by full auto servo Motor .Not by air pressure.

4)One operator need only

5)Anti-wind device make the ribbon pulled into dryer after printing.

6)free set up the printing times and the carry times on electronic Dryer lift while stop

7)Most parts are made in Europe,Japan

8)controlled by both computer and manual.

D,machine configuration:

1) Feed in :1set frame

2) webbings rollers guiding device:1set with frame.

3) printer:1set

4)Dryer system: 1set

1)with tape content of 20meters tape content

2)heated with electrical

3)with temperature control, temperature is adjustable

4)Laid out air blower for heating webbings .

5) take off device:1set 3group of take off wheels for 6 webbings take off purpose

E. Technical specification:

1)Color:1C

2)Max. Printing Area:26CM*130CM

3)Printing linest: 1-6LINES/ TIME

4)MAX. Speed /H.:10M/Line/Minute

5)Max. Power:20KW/380V/3P/50 Hz

Remark:1) Inverter:MISTUSBISH

2)PLC: MISTUSBISH or AB(America)

Dopsing automatic screen printing machines widely used,recogonized with long term cooperated with many the world biggest and famous narrow fabric manufacturers are using our screen printing machines,such as PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL, Elastic tapes manufacturer STRETCHLINE and so on.

DOPSING Machinery Technology Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&label printing machine and mini High-Temperature Ribbon Screen Printer,label slitting machine,all are for fabric label and satin ribbon,lanyard,cotton tape etc.As the leader of the narrow fabric screen printing equipments,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co.,Ltd.And moved into KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Covered by plastic membrane within full container or less container

(woodencase)

Product detail pictures:

Related Product Guide:

Lombardi announces two press sales at Labelexpo India | Labels Screen Printer

L9 names 2017 World Label Awards winners | Labels Screen Printer

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for China wholesale Inkjet Flatbed T Shirt Printer - Lashing Straps Screen Printing Machine with CE Certification – Kin Wah, The product will supply to all over the world, such as: Puerto Rico , Russia , St. Petersburg , With a wide range, good quality, reasonable prices and stylish designs, our solutions are extensively used in beauty and other industries. Our solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

-

professional factory for 4 Color 1 Station Silk...

-

Factory source Screen Flat Bed Printing Machine...

-

OEM Manufacturer Polyester Label Ribbons Small ...

-

Top Quality Semi Auto Silk Screen Printing Mach...

-

Good Wholesale Vendors Nylon Label Ribbons Cont...

-

Competitive Price for Rfid Card With Magnetic S...