Europe style for Polyester Satin Ribbons Small Continuous Dyeing Machine - 6 Heads Narrow Fabric Rolling Machine – Kin Wah Detail:

Basic Info

Product Description

Auto PLC Control system

Dual Sides feed in system

Precisely winding accordingly

Widely used for winding any Narrow Fabric

Webbing’s winding speed/Frequency will be different according to its own diameter increase

Come into Global market since the year of 2013.

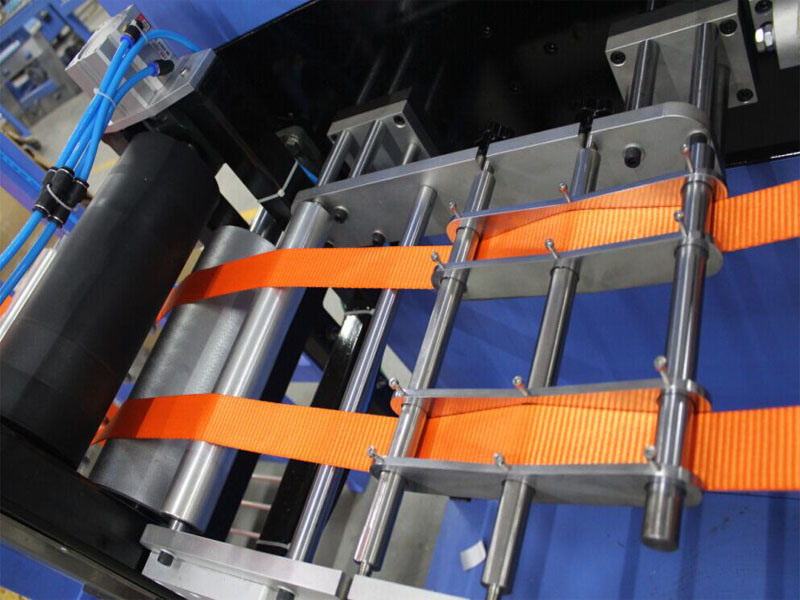

A,Description of Item: 6 Reels Rolling Machine

B,Model: KW-820-100R

C,Features & Functions

1)Application material: Winding any kinds of Narrow Fabric,Labels,satin ribbons,silk ribbons,roll to roll materials/webbings within 100mm width

2)Precisely winding any roll to roll material with width<100mm.

3)convey: powered by full auto Electrical Motor

4)One operator need only

5)6-12 Axes can be assembled freely for purpose of different orders.

6)Anti-slip device make the webbings passed precisely through sensor before winding.

7)freely set up the required length for packing.

8)controlled by both computer and manual.

D,Technical Specification:

1)Max Winding Diameter: 400mm

2)Winding Length: 10-1000m/roll

3)Material’s width: 10-100mm

4)Material’s thickness:0.1-1.0mm

5)MAX. Speed /H.:80m/min/reel

6)Rolling core(inner Φ):10-60mm

7)Max. Power:3.0Kw/380V/3P/50-60HZ

8)Machine Size: 2450*1000*1800mm

9)Weight:230kg

KINWAH Packing machines are widely used,recogonized with long term cooperated with many partners,the world biggest and famous narrow fabric manufacturers are using our machines,such as PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL, Elastic tapes manufacturer STRETCHLINE and so on.

DOPSING Machinery Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&Label printing machine and mini High-Temperature Ribbon Screen Printer,all are for fabric label and ribbon screen printing.As the professional narrow fabric screen printing machine manufacturer,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co., Ltd.And moved intoKINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Covered by plastic membrane within full container or less container (woodencase)

Product detail pictures:

Related Product Guide:

Craft Beer Packaging: Sometimes It’s Not Just What’s Inside That Counts – Covering the Printing Inks, Coatings and Allied Industries | 8 Heads Labels Winding Machine

The Best Under-the-Radar Food Destination in the U.S. | Polyester Satin Ribbons Small Continuous Dyeing Machine

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Europe style for Polyester Satin Ribbons Small Continuous Dyeing Machine - 6 Heads Narrow Fabric Rolling Machine – Kin Wah, The product will supply to all over the world, such as: Iran , Victoria , Niger , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

-

OEM China Satin Printing Machine - 6 Axes Narr...

-

Online Exporter Care Labels Silk Screen Printin...

-

Factory Free sample Labels Screen Printing Mach...

-

Factory source Non Woven Printing Machine - He...

-

Manufactur standard 8 Drums Starching And Finis...

-

Factory source Screen Printing Machine For Clot...