Factory Price For Lanyard Weaving Machine - High Temp Continuous Dyeing&Finishing Machine for Lashing Straps – Kin Wah Detail:

Basic Info

Product Description

Item No: KW-820-DZ400

Size: 28000*1000*4000mm

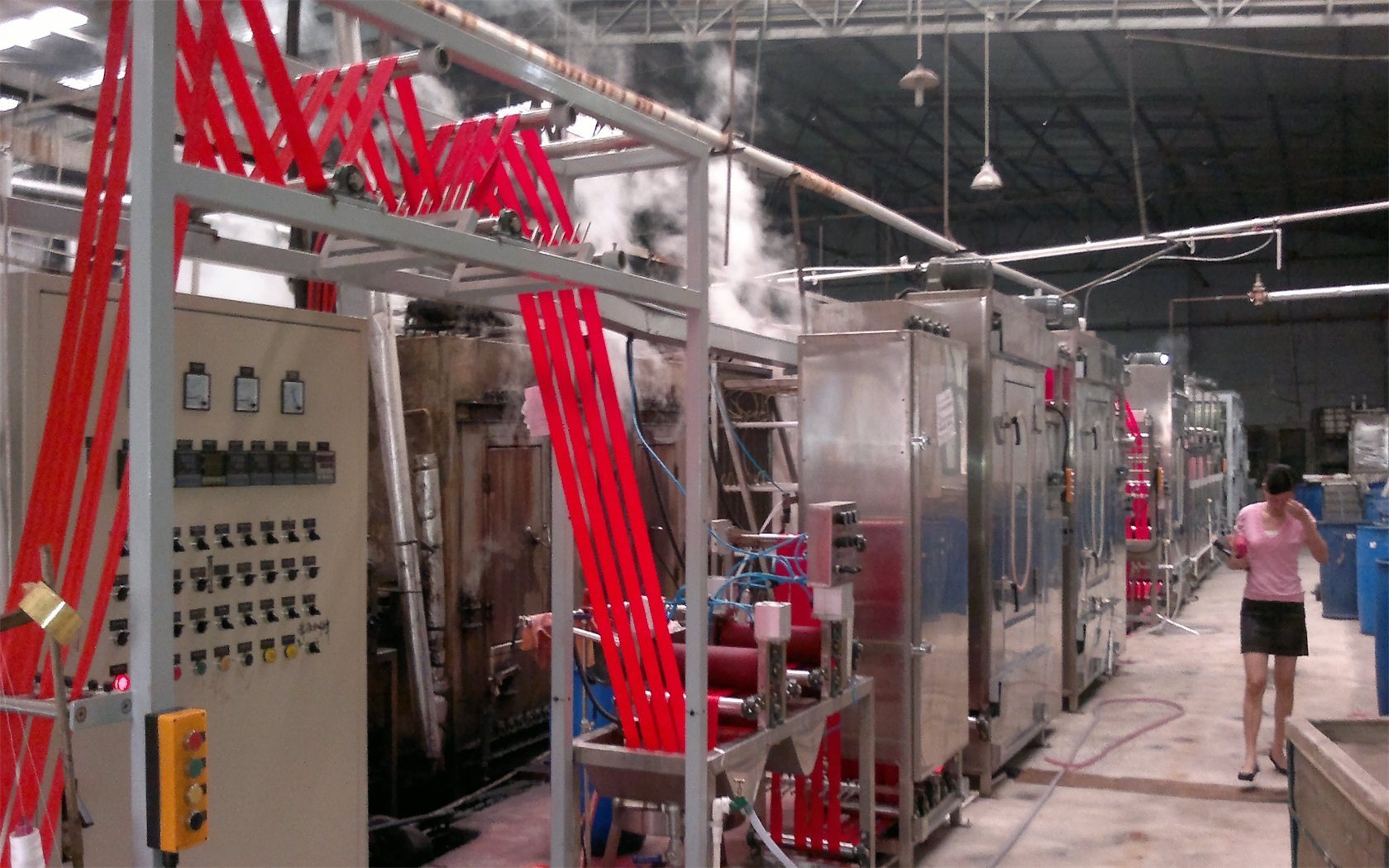

This is high speed horizontal sling webbings/tie down straps/lash straps continuous dyeing&finishing machine

Application: The dyeing machine is especially used for dyeing Textile Lift slings,tie down straps,lash straps,Heavy duty belts with elongation.

With washing tanks for good color fasteness

Product capacity: 2 Pcs/time, 0-12meter/min/Pcs

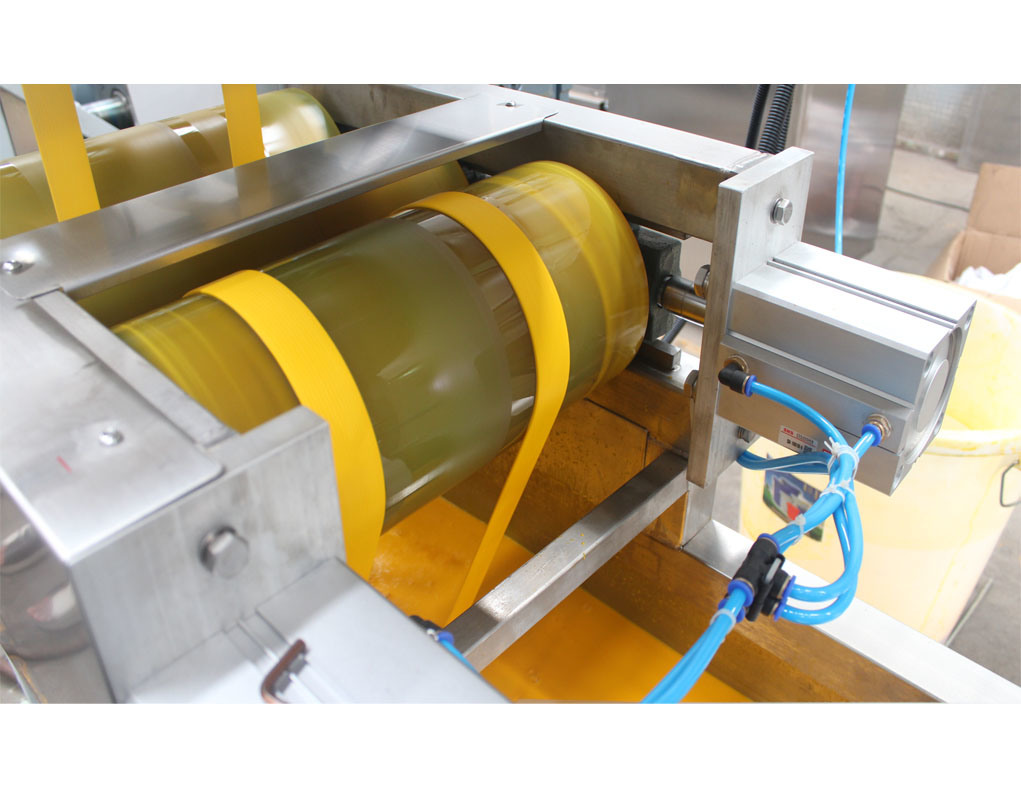

Can dye both 350mm width sling webbings,heavy duty webbings,tie down straps,lash straps,etc.

With strong elongation function.

For 300mm width webbings:1 meter go into dyeing machine,1.02meter come out after dyed.

For 50mm width webbings:1 meter go into dyeing machine,1.06meter come out after dyed.

Heat System electrical/LPG or natural gas

Working Width(mm) 400

Thermofixation Chamber Tape Content(m) 60

Maximun Speed(m/min) 20-40

Maximun Number(m) 8

Remark: laid out elongation function,Control system Computer control

Processes: Feed in-dyeing groove-Infrared pre drying-hold mangle-High Temp Steam chamber(Normal Temp Steam Chamber)thermofixation-pull mangle-washing tank-hold mangle-drying Chamber-cooling system-pull mangle-take off

Package:Covered by plastic membrane within full container or less container (woodencase)

Customers:

lifting slings/webbing slings/lash strap/tie down strap: JULI Group, Murtra, Protekt, Astro, Hedef Halat, Ekas, Tsiros and Ferreterro, Dahua, Lijia, LiQiang,

Automobile Seatbelt Webbing:AUTOLIV GROUP,Oppermann, FEIMA, GuangDa

Label Ribbon:Kings, ITL, LEADERS, XINLI, WUXING,YOU FU, SHUANGLIN

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.

Product detail pictures:

Related Product Guide:

UniNet to Unveil Innovative Dye Sublimation Transfer Print Solution to Fuel Business Growth at ISS Long Beach 2019 | Luggage Belt Continuous Dyeing And Finishing Machine

Gallus Launches New Digital Label Press – Covering the Printing Inks, Coatings and Allied Industries | Polyester Satin Ribbons Small Continuous Dyeing Machine

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is "You come here with difficulty and we give you a smile to take away" for Factory Price For Lanyard Weaving Machine - High Temp Continuous Dyeing&Finishing Machine for Lashing Straps – Kin Wah, The product will supply to all over the world, such as: Ethiopia , Maldives , Eindhoven , Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.