Manufacturer of Bag Webbings Screen Printer - 200mm Automobile Safety Belts Continuous Dyeing&Finishing Machine – Kin Wah Detail:

Basic Info

Product Description

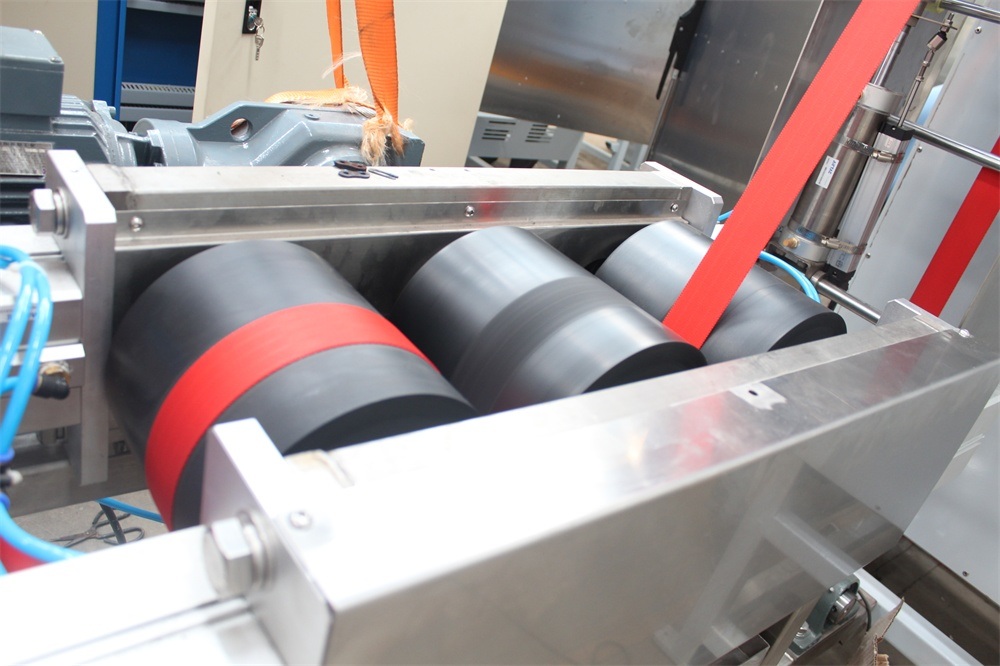

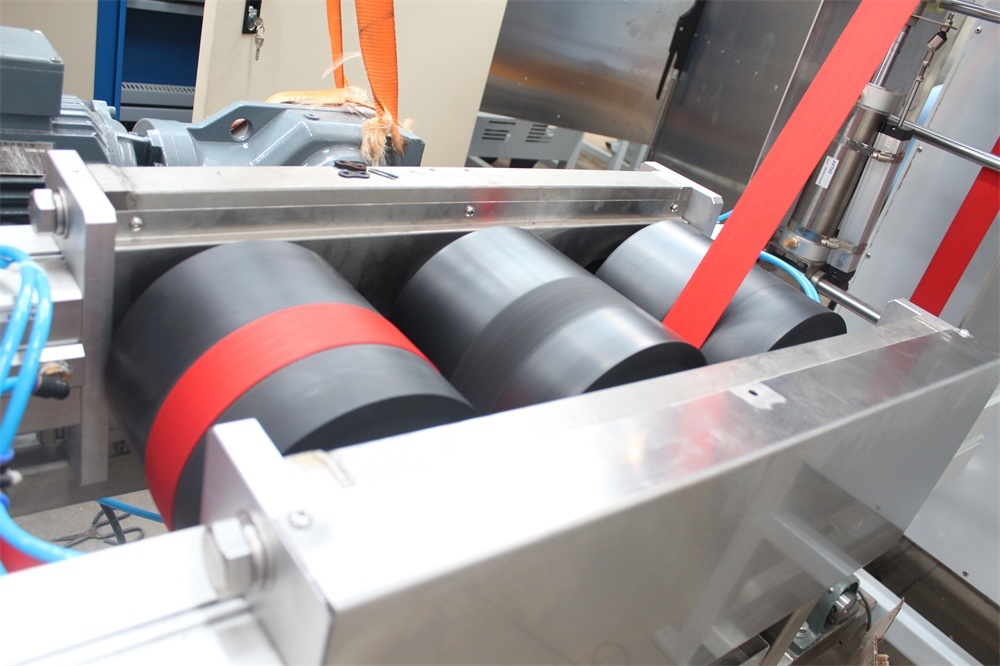

200mm Automobile Safety belts Continuous dyeing&finishing machine

Item No: KW-800-AQS200

Size: 15000*1000*1800mm

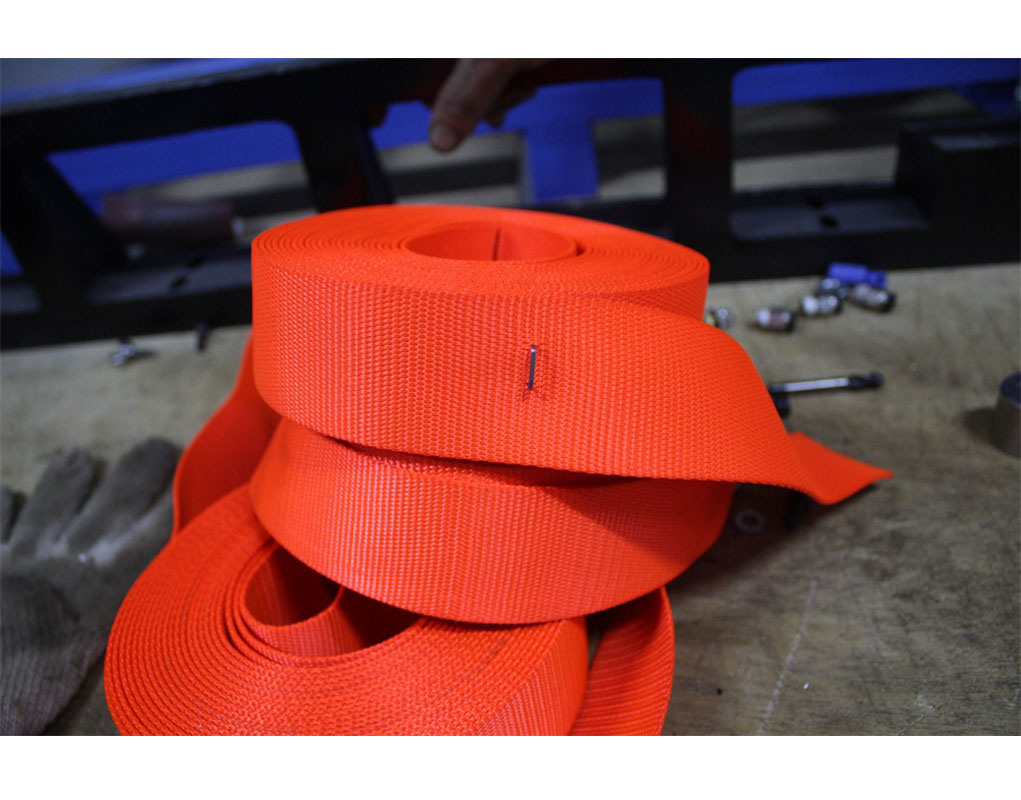

This is high speed luggage&Suitcase belts/webbing continuous dyeing machines for nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings etc.

Features:

1) High efficiency

2) Power Energy Saving

3) Our patents.

4)Application: The dyeing machine is especially used for

luggage&Suitcase belts/webbing continuous dyeing machines

for nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings with thickness below 1.5mm.

5)Product capacity: 1-12 Pcs/time, 0-35meter/min/Pcs.

Heat System electrical/LPG or natural gas/steam

Working Width(mm) 200/400/600

Thermofixation Chamber Tape Content(m) 45/60/60/80

Maximun Speed(m) 15/30/40

Maximun Number(m) 6/10/20

Control system Manual/Computer control(PLC&Touch screen)

Processes: Feed in-dyeing groove-Infrared pre drying-thermofixation chambers-chemical groove-steam chamber-washing tanks-chemical groove-hot air chamber drying&finishing unit-cooling system-take off

Customers: SATIN RIBBONS, ELASTIC TAPES continuous dyieng and finishing machines: MONTRIMS,ITL,GLOBAL LABEL, KINGS, LEADER,XINLIN,SANDING GROUP, BRAITEX, TELALA, WARRANTY, APEX, N R GROUP, SHORE TO SHORE, KNITTING CONCERN, STRETCHLINE, DUGOTEX SO ON.

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.

Package:Covered by plastic membrane within full container or less container (woodencase)

Product detail pictures:

Related Product Guide:

China’s Matsuoka Printing adds digital label printing with world’s first Winbosc Cloud | Labels Screen Printer

Industrious Qingdao: Tracking types for safety | Labels Screen Printer

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Manufacturer of Bag Webbings Screen Printer - 200mm Automobile Safety Belts Continuous Dyeing&Finishing Machine – Kin Wah, The product will supply to all over the world, such as: Holland , United Arab emirates , Slovakia , Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Wholesale Dealers of Polyester Satin Ribbons Sa...

-

Hot New Products Balloon Printing Machine - Si...

-

Cheapest Price Polyester Ribbons Small Continuo...

-

PriceList for Tie Down Straps Screen Printer - ...

-

China Manufacturer for Narrow Label Printing Ma...

-

OEM/ODM Supplier Nylon Label Ribbons Dyeing Mac...