OEM Factory for Lifting Webbings Screen Printer - Tie Down Straps Screen Printing Machine Manufacturer – Kin Wah Detail:

Basic Info

Product Description

Product Description

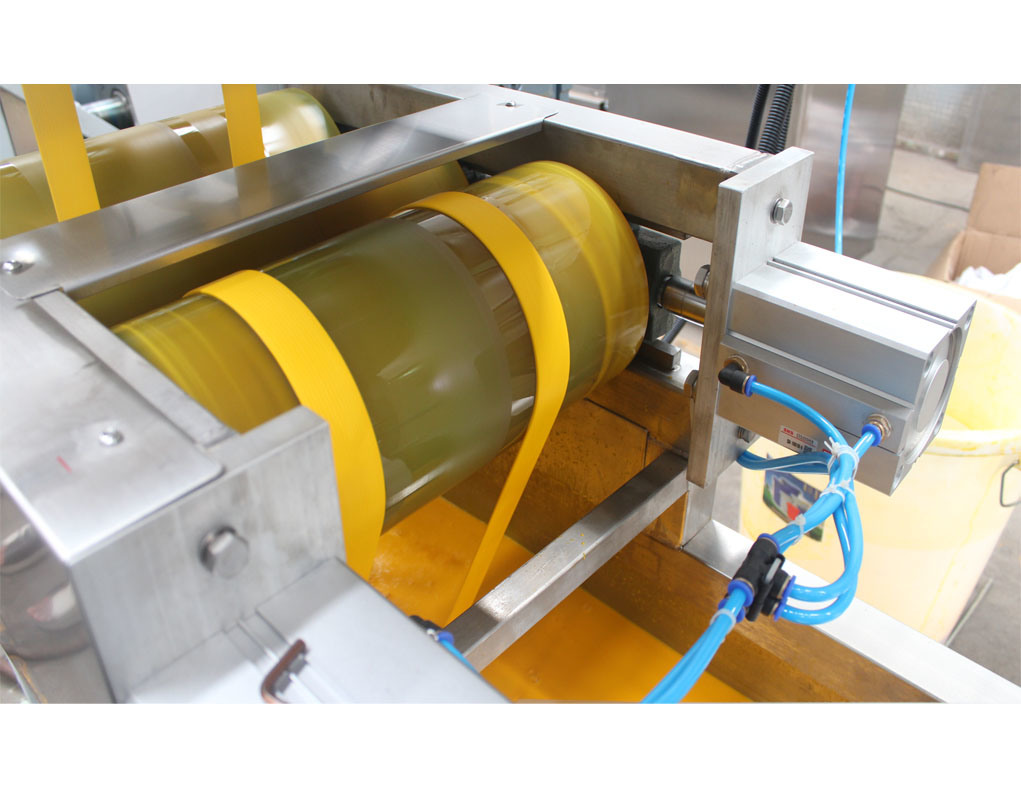

This is a kind of automatic textile lift slings webbings printing machine in screen printing type, with PLC and touch screen

1)Application material: print any kinds of roll to roll webbings, such as seatbelt webbings, tie down straps, luggage and suitacase webbings and so on.

2)Precisely Print any roll to roll material with width<30CM.

3)convey: powered by full auto servo Motor .Not by air pressure.

4)One operator need only

5)Anti-wind device make the ribbon pulled into dryer after printing.

6)free set up the printing times and the carry times on electronic Dryer lift while stop

7)Most parts are made in Europe,Japan

8)controlled by both computer and manual.

D,machine configuration:

1) Feed in :1set frame

2) webbings rollers guiding device:1set with frame.

3) printer:1set

4)Dryer system: 1set

1)with tape content of 20meters tape content

2)heated with electrical

3)with temperature control, temperature is adjustable

4)Laid out air blower for heating webbings .

5) take off device:1set 3group of take off wheels for 6 webbings take off purpose

E. Technical specification:

1)Color:1C

2)Max. Printing Area:30CM*130CM

3)Printing linest: 1-6LINES/ TIME

4)MAX. Speed /H.:10M/Line/Minute

5)Max. Power:20KW/380V/3P/50 Hz

Remark:1) Inverter:MISTUSBISH

2)PLC: MISTUSBISH or AB(America)

Our Services

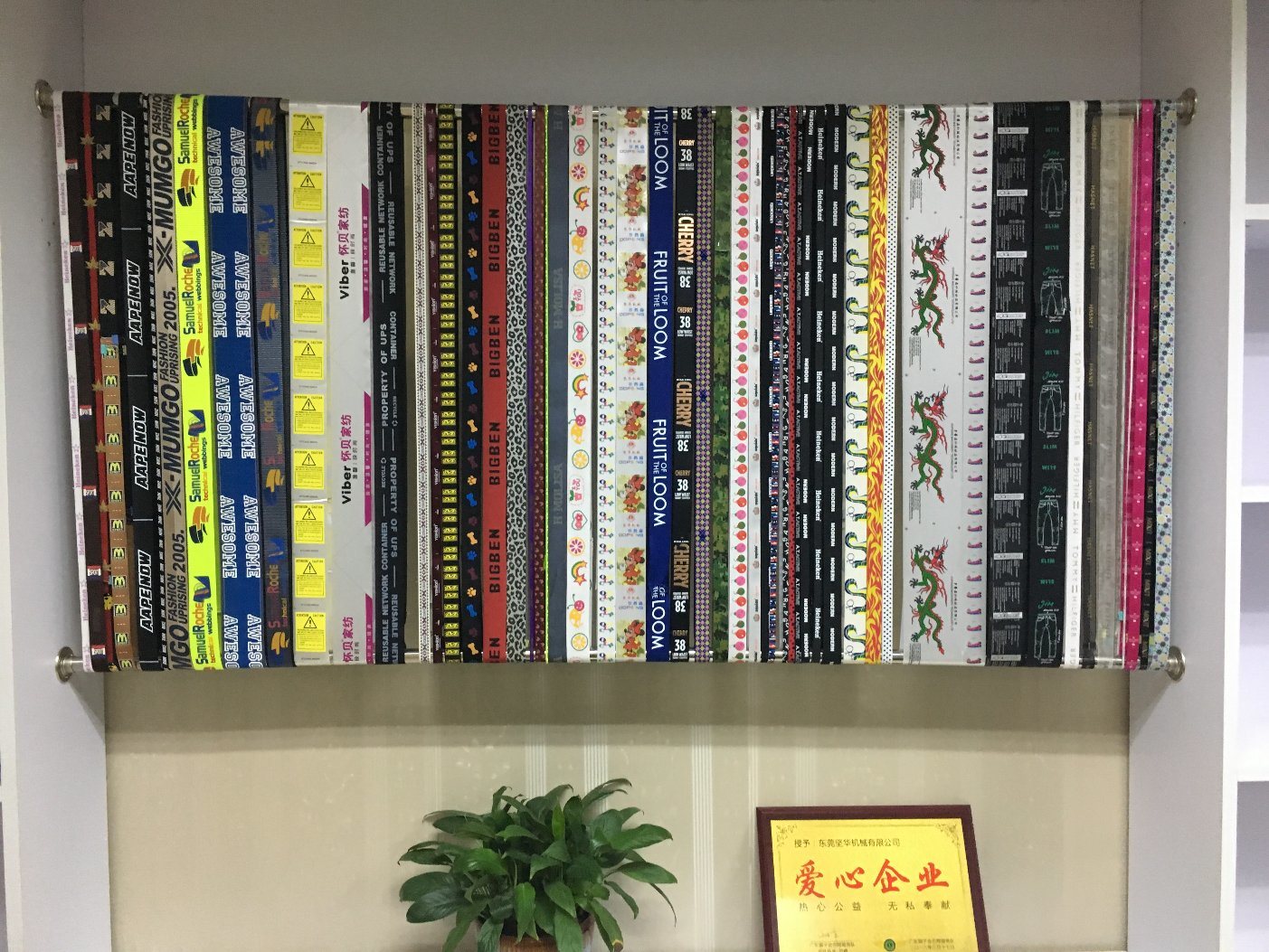

Dopsing automatic screen printing machines widely used,recogonized with long term cooperated with many the world biggest and famous narrow fabric manufacturers are using our screen printing machines,such as PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL, Elastic tapes manufacturer STRETCHLINE and so on.

Company Information

DOPSING Machinery Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&Label printing machine and mini High-Temperature Ribbon Screen Printer,all are for fabric label and ribbon screen printing.As the professional narrow fabric screen printing machine manufacturer,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co., Ltd.And moved into KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Packaging & Shipping

Covered by plastic membrane within full container or less container

(woodencase)

Product detail pictures:

Related Product Guide:

Zacks Investment Research Upgrades Ennis (EBF) to Strong-Purchase | Polyester Satin Ribbons Small Continuous Dyeing Machine

Brother QL-1110NWB Review & Rating | Polyester Satin Ribbons Sample Continuous Dyeing Machine

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for OEM Factory for Lifting Webbings Screen Printer - Tie Down Straps Screen Printing Machine Manufacturer – Kin Wah, The product will supply to all over the world, such as: Libya , Japan , Southampton , Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

-

Cheapest Price Semi Automatic Tyvek Wristband S...

-

factory Outlets for Suitcase Belt Continuous Dy...

-

Factory Outlets Ribbon Labels Winding Machine -...

-

2017 Good Quality Multi-color Silk Screen Print...

-

Hot Selling for Shuttle Embroidery Machine - L...

-

New Fashion Design for 1 Color Roll To Roll Aut...