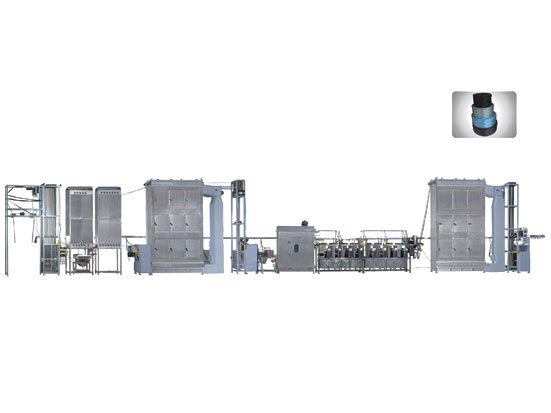

OEM/ODM Supplier Shoulder Tapes Screen Printing Machine - High speed polyester luggage belt continuous dyeing and finishing machine – Kin Wah Detail:

Item No.KW-800-AQS400

This a a kind of Two ends Automobile Seatbelt webbings continuous dyeing machine! European Standard Two Ends Automobile Seatbelt webbings continuous dyeing machines.

Two Ends

High speed

With Elongation

with Calender function

With Computer

our Patent.

High efficinecy

1)Application: The dyeing machine(with PLC) is especially used for dyeing Two-ends type Automobile Seatbelt webbing with European standard requirement.with elongation and relative calender function.

2)Processes: Feed in → accumulator →dyeing padder→infrared predrying → hold mangle→thermofixation →press calender→cool off→ pull mangle → chemical padder →steamer→water washing → chemical padder→ hot air drying →cool off→pull mangle →take off

3)Production capacity:1 pcs-2Pcs /time,0-25meter/min/pcs.

| Heat System | electrical |LPG or natural gas |steam | ||

| Working Width(mm) | 200 | ||

| Thermofixation Chamber Tape Content(m) | 70 | ||

| Maximun Speed(m) | 25 | ||

| Maximun Number(m) | 2 | ||

| Control System | Computer control( PLC & Touch screen) | ||

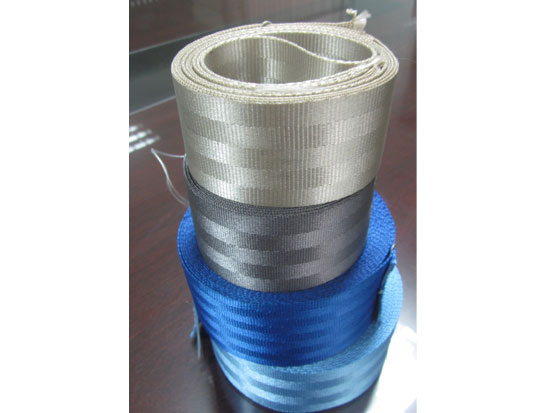

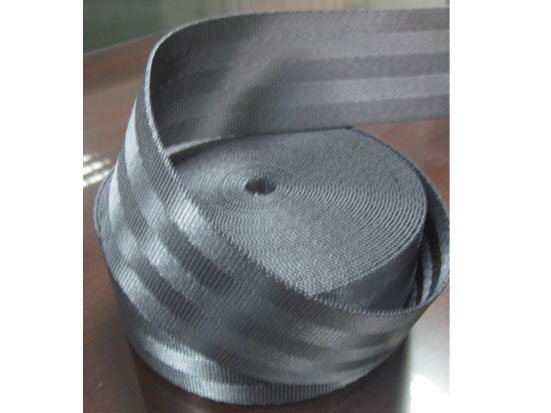

Product detail pictures:

Related Product Guide:

Gallus develops new digital label printing system | 8 Heads Labels Winding Machine

Why Adding Sublimation To A Decorating Business Can Be A Smart, Profitable Move – Covering the Printing Inks, Coatings and Allied Industries | Polyester Satin Ribbons Sample Continuous Dyeing Machine

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for OEM/ODM Supplier Shoulder Tapes Screen Printing Machine - High speed polyester luggage belt continuous dyeing and finishing machine – Kin Wah, The product will supply to all over the world, such as: New Zealand , Austria , Karachi , Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

China wholesale Polyester Elastic Tapes Continu...

-

China OEM 6 Heads Rolling Machine - Normal Tem...

-

Europe style for Glass Bottles Silk Screen Prin...

-

Hot sale Narrow Fabric Sample Continuous Dyeing...

-

factory Outlets for Inkjet A2 Uv Printer - 5 C...

-

Best Price for Label Ribbons Continuous Dyeing ...