Renewable Design for Manual Silk Screen Hot Stamping Printing Machine - Cotton Label/Lanyard Ribbon Screen Printing Machine – Kin Wah Detail:

Basic Info

Product Description

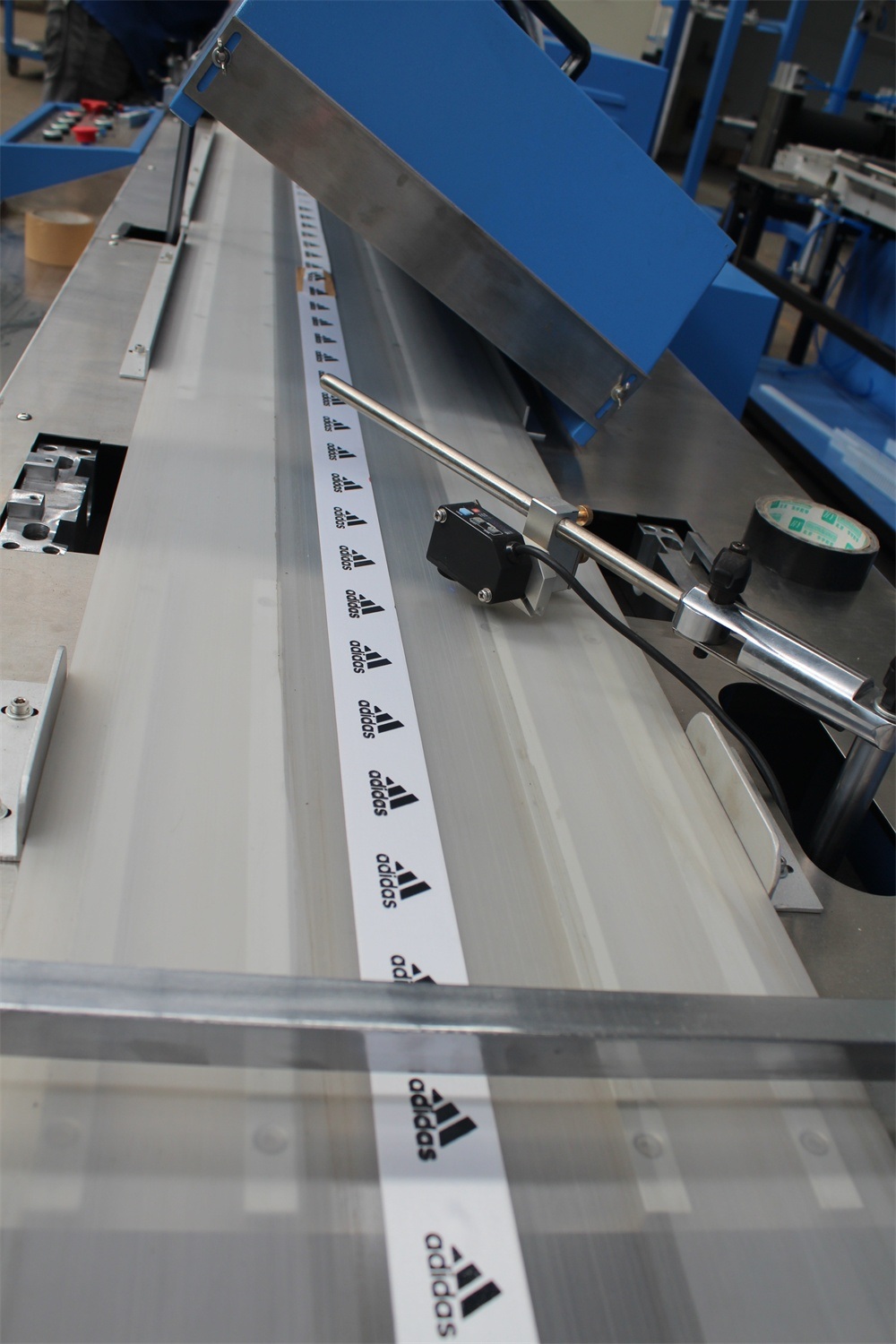

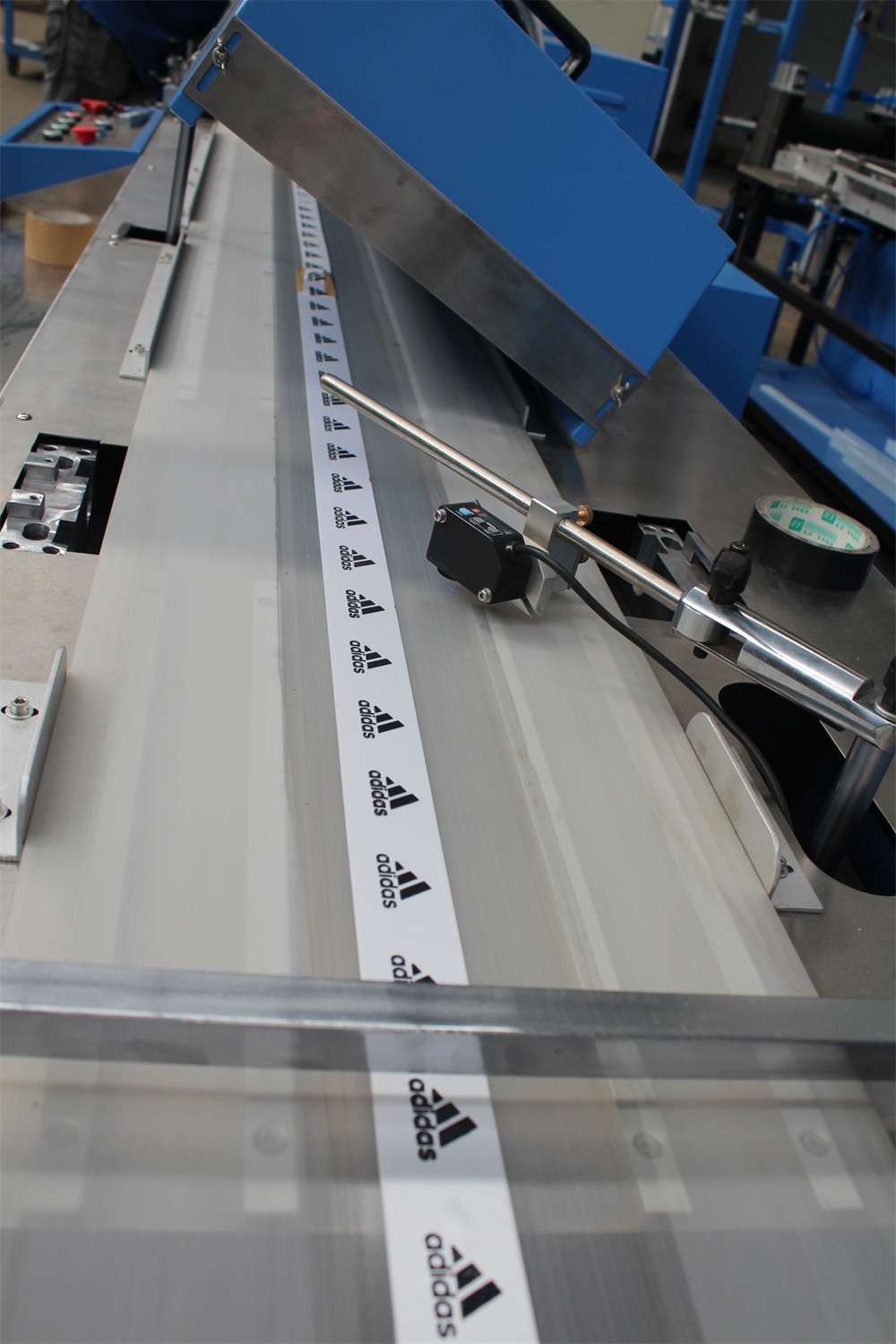

It’s a kind of big production all kinds of narrow fabric such as labels, ribbons, elastic tapes ,PET film, laces,lanyards,cotton tape, elastic tape, webbing sling, small slice and so on all kinds of roll to roll material single colore Automatic screen printing machine (It’s our patents)

Servo system

Two long dryer for big production

big printing area

long convey belt to avoid frequancy glue coating.

dryers laid after printer is more convenient for production and mchine operation and ribbons connection and so on.

frame can be lift up for frame clean purpose.

can print elastic tapes after installation of elastic tapes attachment.

Come into Global market since the year of 2012.

it can print any kind of roll to roll material, such as label ribbons,satin ribbons,lanyard ribbons,elastic tapes, heat transfer film,shoes laces, heavy webbings and so on.

A,Description of Item: Automatic single colore screen printing machine

B,Model: WET-4000S-02

C,Features & Function

1)Application material: print any kinds of roll to roll narrow fabric, such as label ribbons, satin ribbons, cotton tapes and so on.

2)Precisely Print any roll to roll material with width<30CM.

3)convey: powered by full auto servo Motor .Not by air pressure.

4)One operator need only

5)Frame can be automatic lift up for purpose of easy cleaning the screen. Don’t need to take out frame from machine.

5)Anti-wind device make the ribbon pulled into dryer after printing.

6)free set up the printing times and the carry times on electronic Dryer lift while stop

7)Most parts are made in Europe,Japan

8)controlled by both computer and manual.

9)Laid out 2 long dryers 1(meter +1.4meter) for bigger production.

10)controlled by both computer and manual operation.

11)laid out take off device for ribbons automatic winding into rolls.

D,Technical Specification:

1)Colore:1C

2)Max. Printing Area:28CM*65CM

3)Printing linest: 3LINES/3.5CM

4)MAX. Speed /H.:13M/Line/min

5)Max. Power:14Kw/380V/3P/50-60HZ

6Machine Size:7000*1200*1300mm

DOPSING Machinery Technology Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&label printing machine and mini High-Temperature Ribbon Screen Printer,label slitting machine,all are for fabric label and satin ribbon,lanyard,cotton tape etc.As the leader of the narrow fabric screen printing equipments,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co.,Ltd.And moved into KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Product detail pictures:

Related Product Guide:

The Best Under-the-Radar Food Destination in the U.S. | Labels Screen Printer

Chile: Despite super harvest cherry producers can’t cover their costs | Polyester Satin Ribbons Sample Continuous Dyeing Machine

Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Renewable Design for Manual Silk Screen Hot Stamping Printing Machine - Cotton Label/Lanyard Ribbon Screen Printing Machine – Kin Wah, The product will supply to all over the world, such as: Naples , Austria , Jordan , Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.