Short Lead Time for Textile Printing Machinery - Heavy Duty Belts Automatic Cutting and Winding Machine – Kin Wah Detail:

Basic Info

Product Description

Product Description

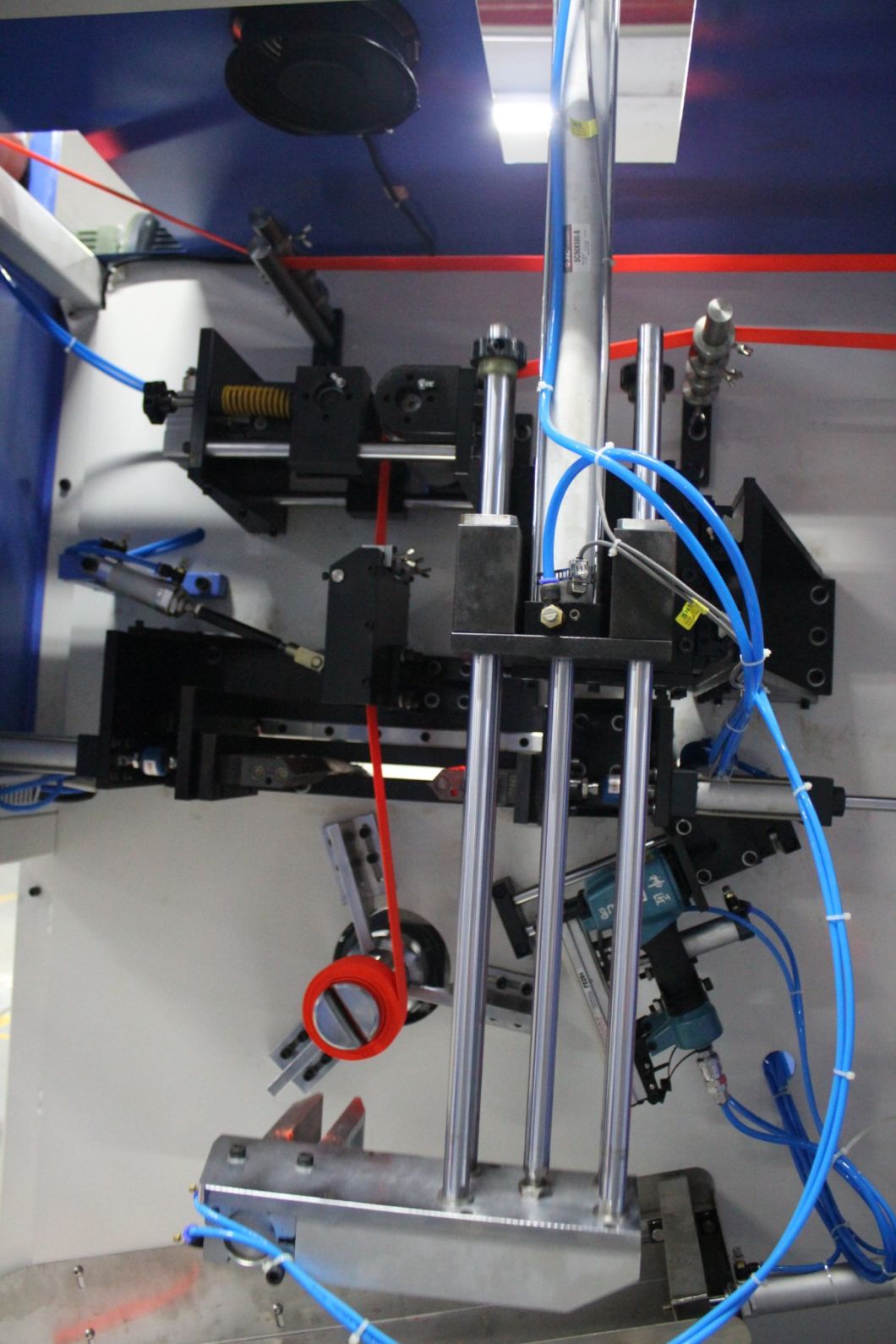

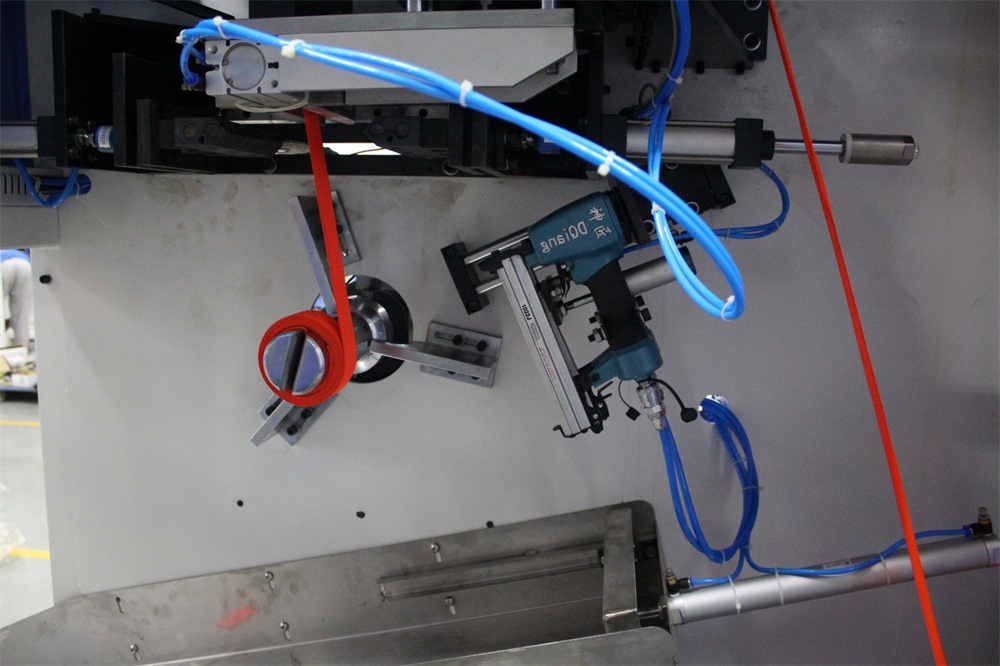

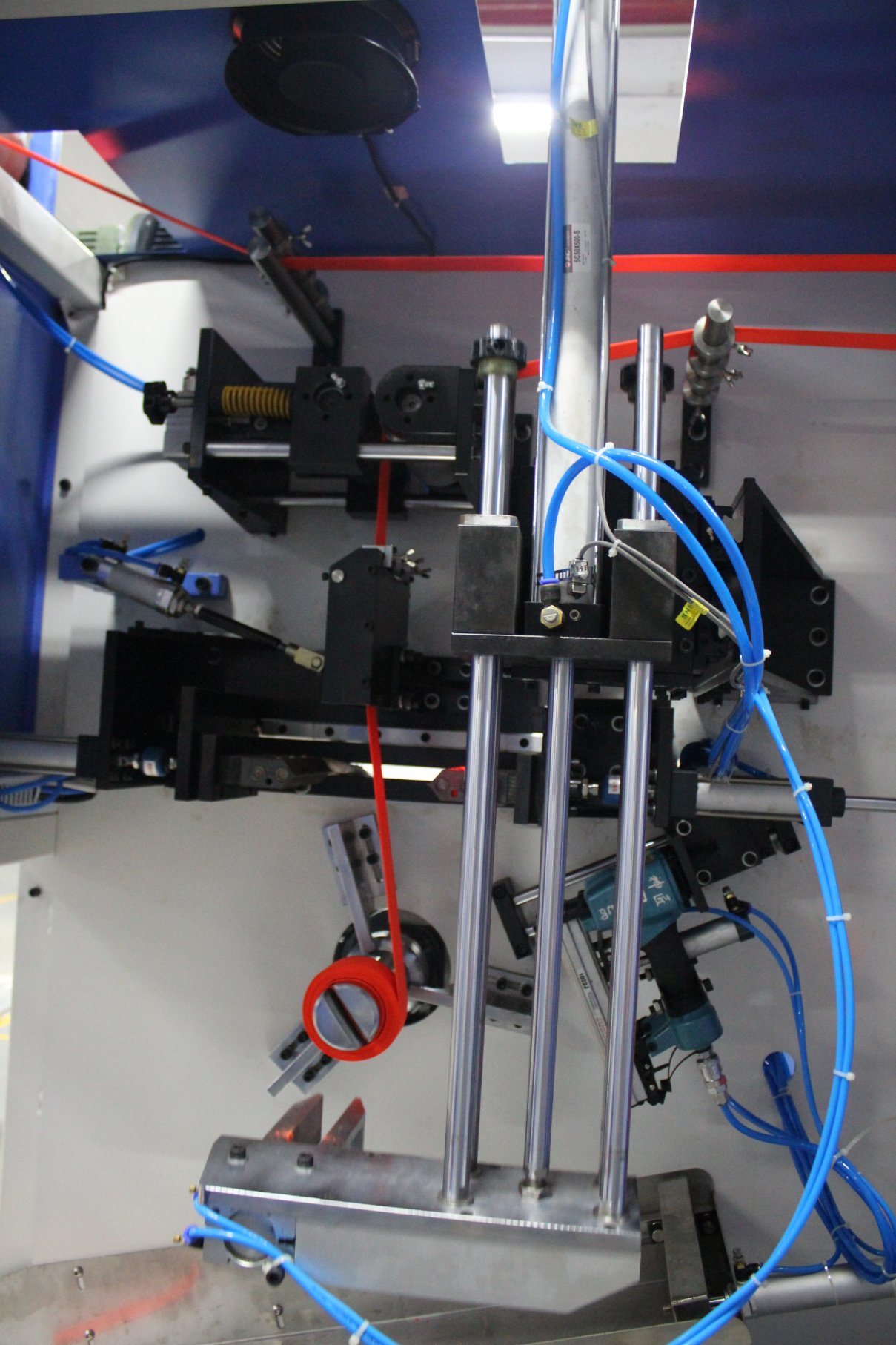

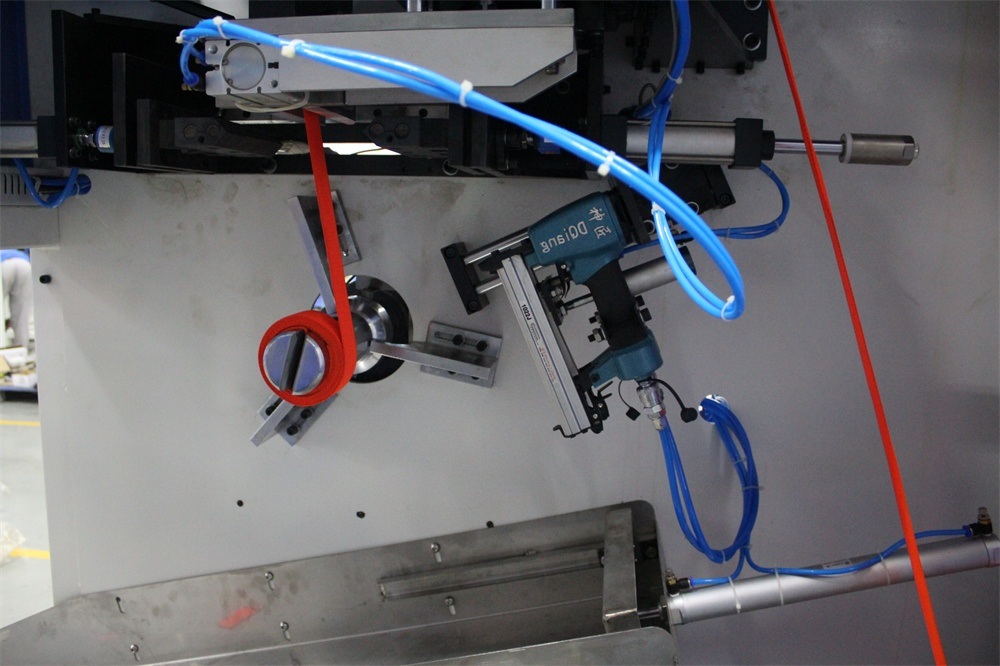

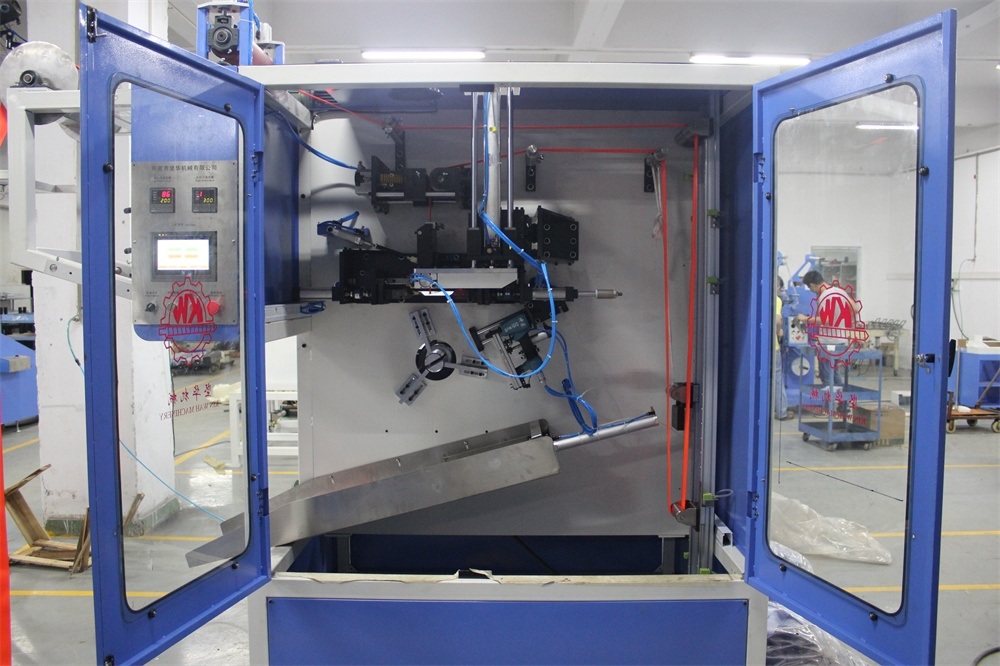

KW-820-160L , It’s a kind of cutting and winding machinery for all kinds of heavy duty webbings such as sling webbings,lashing straps/tie down straps, safety belts,luggage belts/webbings,textile lift sling webbings.

Servo system

U box design for feed in safely

The built-in Heating system makes thick material can be cut easier

precisely cutting area and length.

widely used for cutting any heavy duty webbings

Webbing’s rotating speed will be different according to its own diameter increase

Come into Global market since the year of 2012.

A,Description of Item: Seatbelt cutting and winding machine

B,Model: KW-820-160L

C,Features & Functions

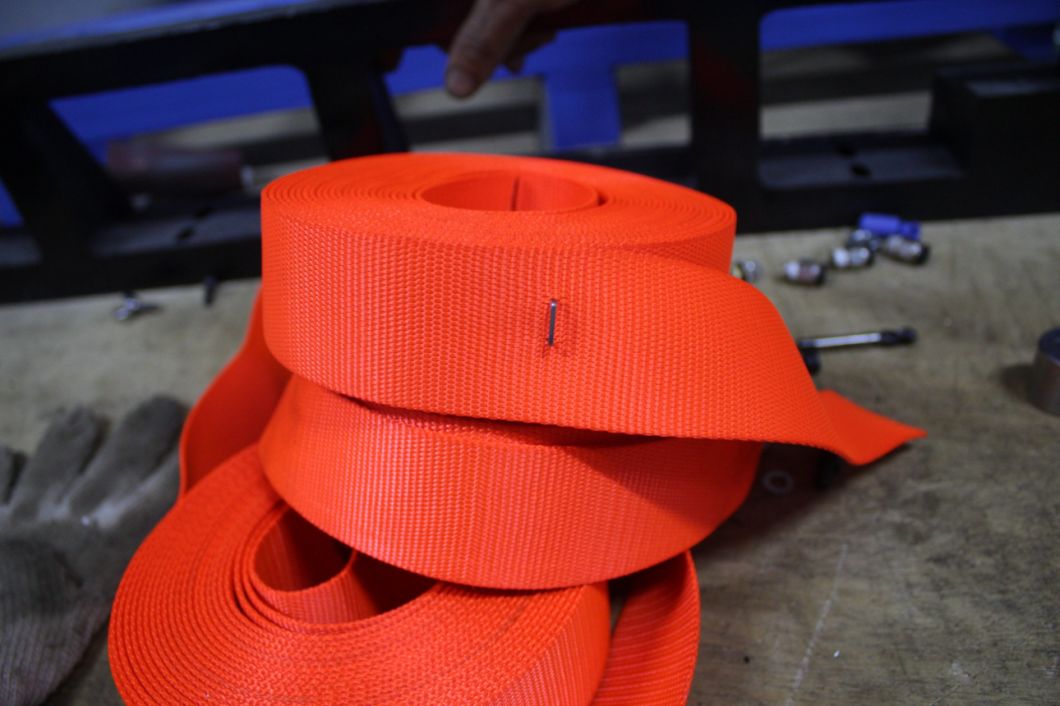

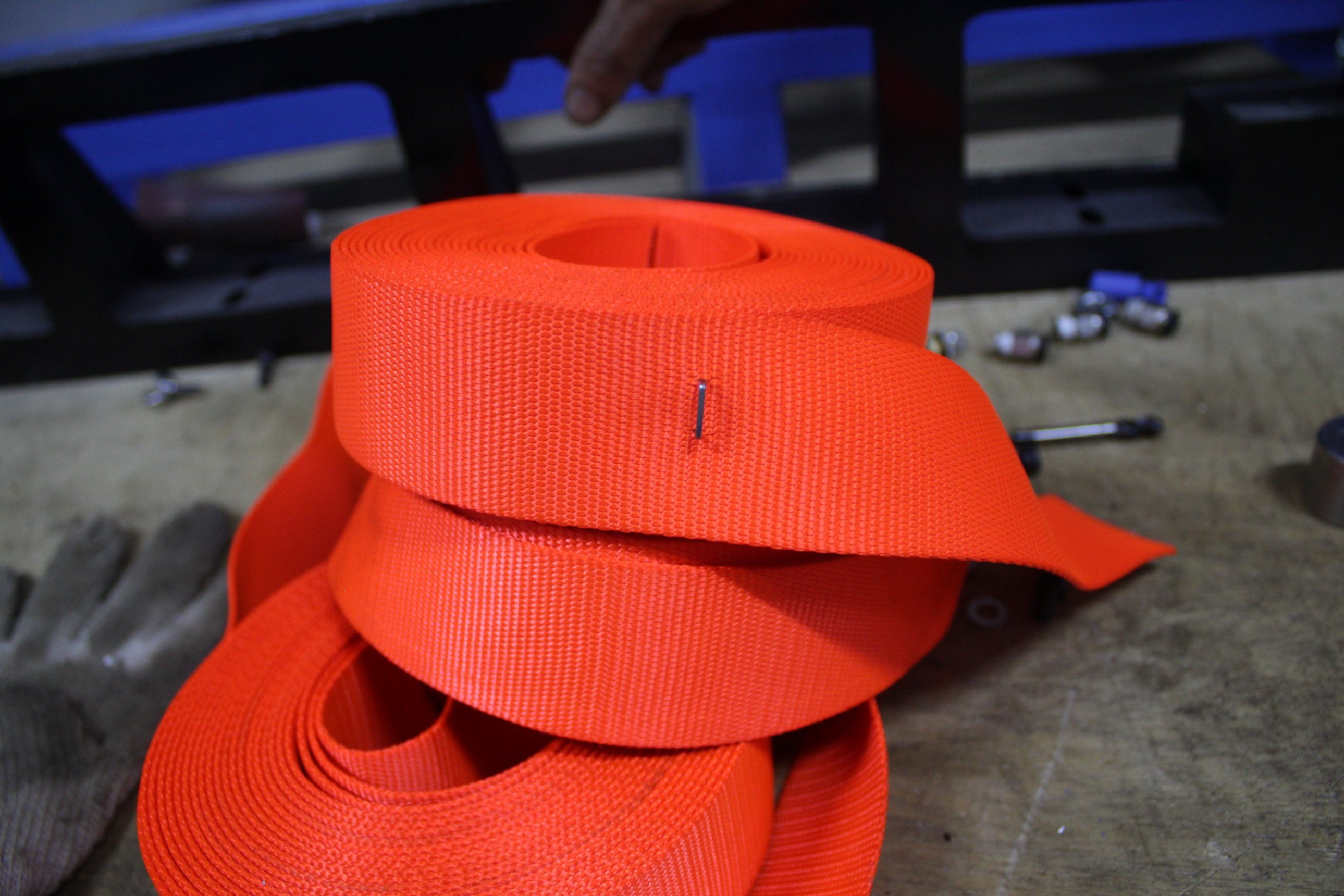

1)Application material: cutting any kinds of heavy duty webbings such as sling webbings,lashing straps/tie down straps, safety belts,luggage belts/webbings,textile lift sling webbings

.

2)Precisely cutting any roll to roll material with width<100mm.

3)convey: powered by full auto servo Motor .Not by air pressure.

4)One operator need only

5)Cutter can be automatic lift up for purpose of easy cleaning.

6)Anti-slip device make the webbings passed precisely through cutter before cutting.

7)freely set up the cutting length and the times gap on the screen.

8)controlled by both computer and manual.

11)After cutting device for webbings automatic winding into rolls.

D,Technical Specification:

1)Cutter:1 Piece

2)Max. Cutting Area: 50mm/line

3)Cutting linest: 2LINES/TIME

4)MAX. Speed /H.:2m/s/Line

5)Max. Power:1.5Kw/380V/3P/50-60HZ

6Machine Size: 7000*800*1800mm

Our Services

Dopsing automatic screen printing machines are widely used,recogonized with

long term cooperated with many partners,the world biggest and famous narrow

fabric manufacturers are using our screen printing machines,such as

PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL, Elastic tapes

manufacturer STRETCHLINE and so on.

Company Information

DOPSING Machinery Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&Label printing machine and mini High-Temperature Ribbon Screen Printer,all are for fabric label and ribbon screen printing.As the professional narrow fabric screen printing machine manufacturer,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co., Ltd.And moved intoKINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Packaging & Shipping

Covered by plastic membrane within full container or less container (woodencase)

Product detail pictures:

Related Product Guide:

Label and package printing industry predictions for 2019 | Labels Screen Printer

Our 12 favourite record sleeves of 2018 Our 12 favourite record sleeves of 2018 | Polyester Satin Ribbons Small Continuous Dyeing Machine

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for Short Lead Time for Textile Printing Machinery - Heavy Duty Belts Automatic Cutting and Winding Machine – Kin Wah, The product will supply to all over the world, such as: Cyprus , UK , Serbia , With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our goods, make sure you contact us now. We're looking forward to hearing from you soon.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

-

Manufacturer of Two Colors Woven Ribbons Silk S...

-

Popular Design for Tie Down Webbings Automatic ...

-

Good Wholesale Vendors Labels Dyeing Machine - ...

-

Short Lead Time for Flat /round /oval Screen Pr...

-

Manufactur standard Cylindrical Screen Printing...

-

2017 New Style Garment Ribbons Continuous Dyein...